IFS and Artificial Intelligence: Optimized Asset Reliability

Converting Operational Asset Data into Real-Time Asset Intelligence

In the era of intelligent enterprises, asset-intensive organizations face a fundamental challenge: how to convert a flood of operational data into timely, actionable insight. Every connected machine, sensor, and human process generates information but without artificial intelligence (AI) to interpret it, that data remains static, fragmented, and underutilized.

IFS is helping businesses close this gap by embedding AI directly into Enterprise Asset Management (EAM) transforming raw data into predictive, prescriptive intelligence that drives uptime, performance, and long-term asset reliability.

The Data Explosion and the Reliability Imperative

From 8.6 billion connected devices in 2019 to nearly 30 billion projected by 2030, IoT connectivity has turned asset rich industries into data rich ecosystems. The challenge is no longer a lack of data but rather the ability to synthesize vast, disparate data sets into intelligence that improves asset performance.

Yet most enterprises still struggle with siloed operational data, making it difficult to obtain a complete, real-time picture of asset health. AI removes this barrier by continuously processing structured and unstructured inputs from every source sensors, equipment logs, production data, and even human reports to reveal patterns and anomalies invisible to traditional analytics.

AI as the Engine of Real-Time EAM

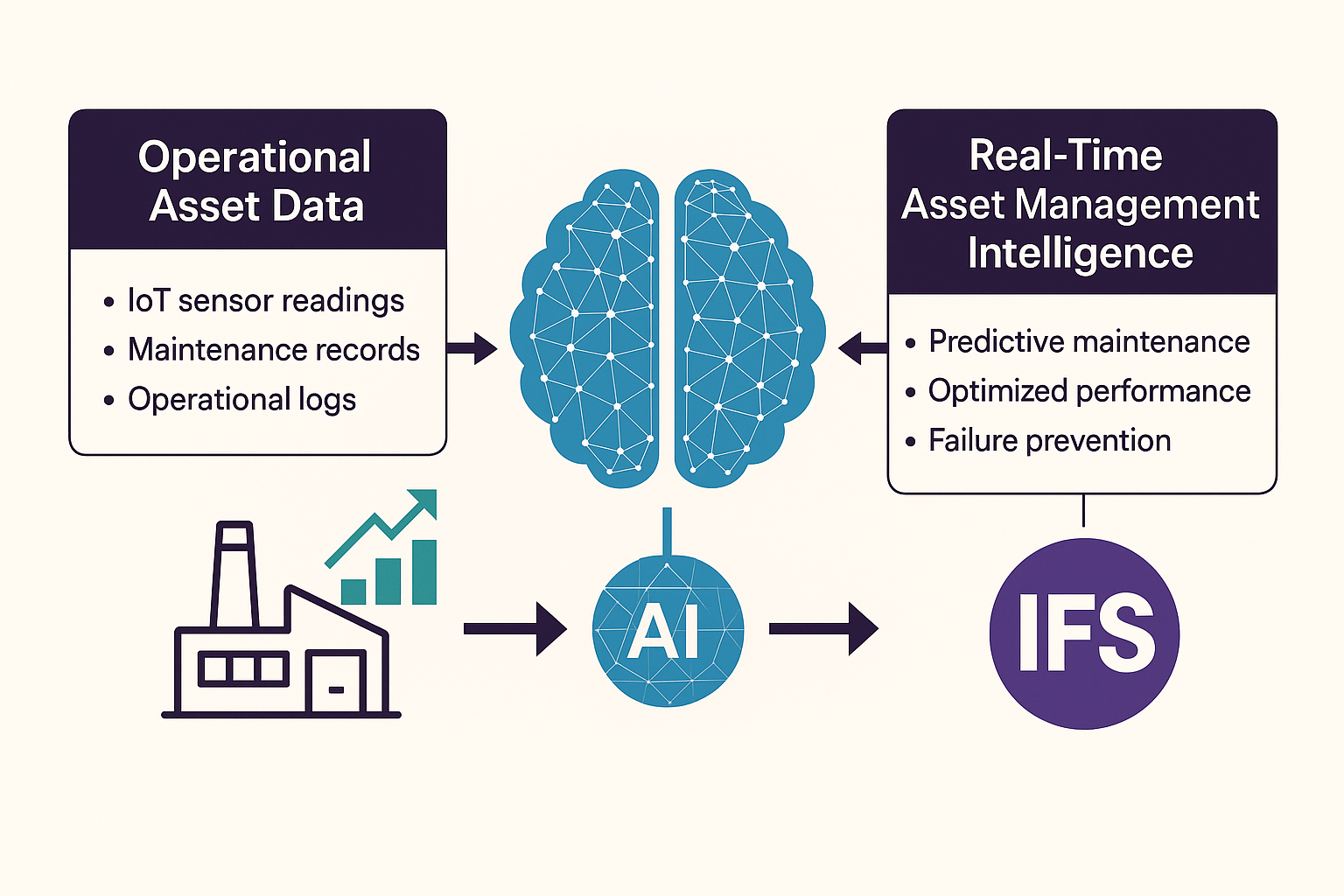

When embedded into IFS Cloud EAM, AI converts this operational noise into strategic foresight. Through machine learning, predictive forecasting, statistical modeling, and anomaly detection, the system automatically analyzes asset behavior and contextualizes the findings across the enterprise.

AI-powered EAM enables three key capabilities:

- Real-Time Analysis and Response

AI algorithms detect anomalies the moment they appear, triggering immediate recommendations to minimize disruption and reduce downtime. - Predictive and Proactive Maintenance

Instead of relying on reactive or time-based maintenance cycles, predictive models forecast failures before they occur—cutting unplanned downtime that can exceed $100K per hour for some industries. - Unrivaled Asset Reliability

AI informs advanced reliability methods such as Failure Modes, Effects, and Criticality Analysis (FMECA), helping teams identify and address potential issues before they impact operations.

From Information to Intelligence

AI doesn’t just process data it structures it for decision-making. Metrics like uptime, mean time between failures (MTBF), overall equipment effectiveness (OEE), and first-pass yield are continuously analyzed to recommend whether to repair, replace, or delay maintenance.

AI transforms raw operational data into real-time asset intelligence bridging the gap between machine data and predictive reliability.

By integrating with adjacent enterprise systems finance, supply chain, HR, and energy management AI extends EAM’s visibility across every operational layer. This contextual intelligence supports everything from optimized maintenance scheduling to efficient spare parts inventories and staffing plans.

The Benefits of AI-Driven Asset Management

Organizations leveraging IFS’s AI-enhanced EAM capabilities realize measurable business outcomes:

- Reduced maintenance costs through predictive and condition-based strategies

- Extended asset lifecycles with optimized usage and servicing plans

- Enhanced operational agility with remote monitoring and “what-if” scenario planning

- Higher sustainability by tracking and minimizing energy consumption and carbon emissions

AI transforms EAM from a maintenance tool into a strategic command center where every machine, line, and process contributes to enterprise wide intelligence and resilience.

Why IFS Leads in Intelligent Asset Reliability

IFS’s cloud native architecture makes it easy to integrate AI across enterprise systems. The result is a unified data model where maintenance, planning, and lifecycle management all feed into a single, intelligent platform.

According to IDC’s Research VP Aly Pinder, IFS’s strength lies in “the breadth of service capabilities that incorporate AI, machine learning, and IoT.” IFS Cloud EAM customers already leverage these embedded AI features to contextualize intelligence, simulate outcomes, automate production, and eliminate unplanned downtime.

Conclusion: Turning Data Into Uptime

Artificial intelligence has redefined the role of asset management from reactive maintenance to predictive reliability. For asset-heavy organizations, the ability to transform operational data into real-time asset intelligence isn’t optional it’s existential.

With IFS Cloud EAM, businesses gain a living, learning system that continuously improves asset performance, sustainability, and profitability. In short, AI ensures your assets don’t just work they think.