Digital Transformation in Defense Manufacturing: From Fragility to High-Performance at Scale

The defense sector is undergoing a rapid transformation. Just a few years ago, U.S. defense manufacturers faced a stark downturn, losing more than 40% of their market value as COVID-19 restrictions forced production slowdowns and supply chain disruptions. Today, the narrative has reversed. Demand is surging, and manufacturers are under pressure to accelerate output.

Yet, with this resurgence comes a central challenge: how to boost production without compounding cost, risk, or inefficiency. The answer lies in digital transformation. Industry leaders from Deloitte to the Department of Defense, underscore that defense organizations must embrace integrated digital technologies to unlock agility, resilience, and precision across the value chain.

The path forward requires moving away from siloed, inconsistent systems toward enterprise-wide integration, linking the shop floor to the top floor through Manufacturing Execution Systems (MES), Enterprise Asset Management (EAM), ERP, and CRM platforms. This shift establishes the elusive single source of truth, enabling real-time, dynamic decision-making.

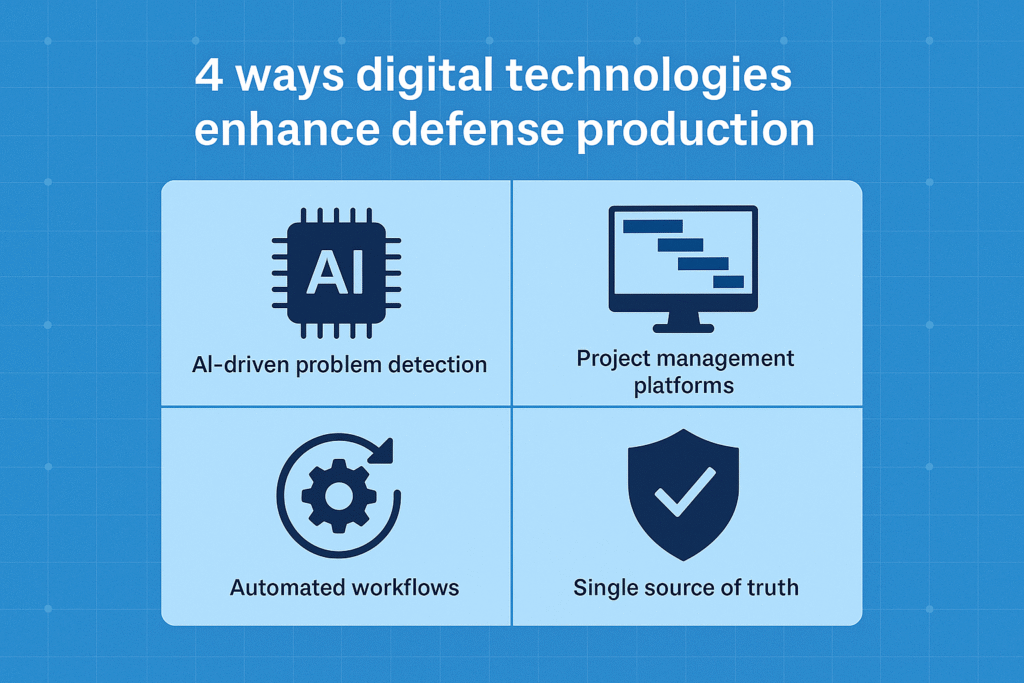

Four Pinch Points Where Digital Solutions Are Reshaping Defense Manufacturing

“Four critical areas where digital transformation is driving efficiency, agility, and compliance across defense manufacturing.”

1. AI-Powered Operations: From Problem Detection to Risk Management

Defense forces and manufacturers alike are accelerating AI adoption. With the U.S. DoD budgeting $1.8 billion for AI, applications are extending well beyond analytics—helping organizations recognize patterns, learn from experience, and predict disruptions.

This comes at a critical moment. To protect against supply shocks, many manufacturers abandoned lean, just in time time inventory models in favor of costly overstocking. Digital tools like demand-driven material requirements planning (DDMRP) now offer a middle ground: dynamically aligning inventory levels with actual usage data. This balances risk, reduces waste, and increases sensitivity to supply chain disruptions all while controlling costs.

2. Integrated Project Management: Driving Efficiency Across Complex Programs

Defense manufacturing projects are inherently complex, requiring orchestration across multiple production lines and assembly stages. Traditional ERP systems often create fragmentation, leaving gaps in planning, scheduling, and workforce alignment.

Integrated project management platforms address this gap by connecting planning directly with execution. The result: enhanced visibility, rapid responsiveness to shifting priorities, and improved coordination of both human and machine resources. Automated scheduling reduces bottlenecks, ensuring capacity is fully optimized and resources are not wasted.

3. Automated Workflows: Real-Time Intelligence From Shop Floor to Top Floor

The transition from siloed reporting to real-time, integrated workflows is redefining operational agility. Unlike ERP systems dependent on static data aggregation, MES platforms with built-in workflow engines provide live insights and trigger automated actions.

This unlocks two benefits: first, accelerating production tasks with precision; second, streamlining non-production processes such as procurement, HR, and facilities management. By embedding standardized workflows, organizations reduce human error, eliminate repetitive tasks, and free skilled staff to focus on high-value activities.

4. Regulatory Compliance: Creating a Single Source of Truth

In defense manufacturing, compliance is not optional it is existential. Regulatory frameworks demand fully traceable, auditable operations, yet many manufacturers still rely on fragmented systems that slow reporting and increase the risk of inaccuracies.

Digital platforms provide the remedy. By combining MES and ERP into a unified environment, organizations gain a real-time, single source of truth. This ensures standardized data exchanges, alignment with ISA-95 standards, and automated generation of government reporting templates eliminating both compliance bottlenecks and risk exposure.

The Imperative: Make High-Performance Manufacturing the Norm

The defense industry stands at an inflection point. Rising demand presents unprecedented opportunities, but only organizations that embed digital technologies at the core of their operations will capture the full upside.

AI, integrated project management, automated workflows, and regulatory ready platforms are no longer optional they are the foundation of high performance defense manufacturing. Organizations that act decisively today will not only manage surging demand but also build resilience, efficiency, and compliance into their long term operating models.

In short: the winners in defense manufacturing will be those that treat digital transformation not as a tactical upgrade, but as a strategic imperative.