IFS.ai: The Game Changing Vision for 2027

The morning sun hits the factory floor, but the typical “morning rush” of frantic planners and stressed supervisors is nowhere to be found. Instead, there is a rhythmic, almost quiet efficiency.

It’s 2027. This is what we call Level 4 Maturity.

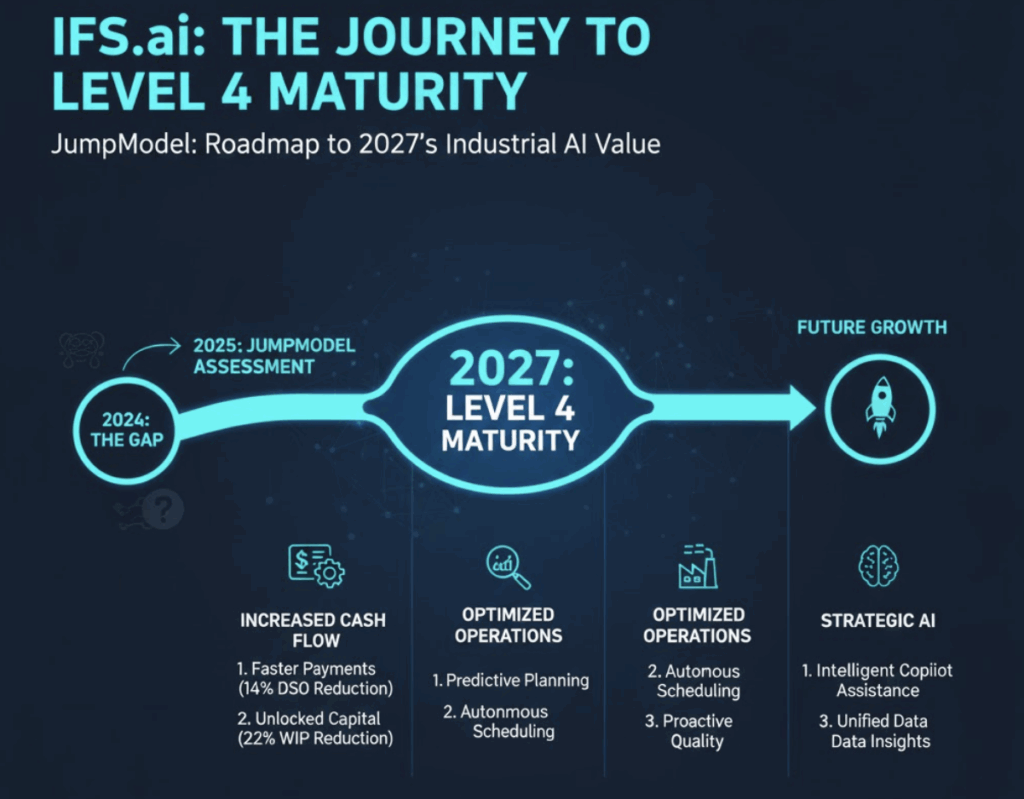

Three years ago, most IFS customers were stuck in “The Gap”—either too far behind to consider AI or experimenting with isolated pilots that never moved the needle. At JumpModel, we spent 2024 and 2025 performing the assessments that changed everything. We found the gaps, mapped the “To-Be” processes, and cleaned the data.

Today, AI isn’t a chatbot on a screen; it’s the invisible heartbeat of the operation.

The CFO’s Question: A New Financial Reality

I was sitting in the boardroom yesterday with Mark, the CFO of a mid-sized industrial manufacturer. He wasn’t looking at spreadsheets; he was looking at a 3D simulation of a proposed third production line.

He turned to the screen—interfacing directly with the IFS.ai Copilot—and asked the question that would have been impossible a few years ago:

“How can I finance my new production line with supply chain-driven cash flow increases?”

In 2024, that would have triggered three weeks of manual data mining and “guestimation.” In 2027, the system responded instantly, pulling from a unified data model that JumpModel helped architect.

The Answer: Connecting the Dots

The system didn’t just give a number; it showed a strategy. It highlighted three specific levers that were already in motion:

- Eliminating the “Float” with Payment Prediction: By utilizing Customer Payment Delay Prediction, the finance team has reduced Days Sales Outstanding (DSO) by 14%. The AI identifies which customers will delay payment before they do, allowing for proactive follow-ups that have stabilized the monthly cash position.

- Unlocking Capital from the Warehouse: Through Finite Production Capacity Planning and Scheduling (MSO), the factory floor is now perfectly synchronized with inbound supply. By predicting shop order operation times with 98% accuracy, the company has slashed Work-In-Progress (WIP) inventory by 22%. That’s millions of dollars in “trapped” cash now sitting in the bank, ready to fund the new line.

- Prescriptive Procurement: The IFS.ai Copilot for Supplier Quotation Evaluation has moved procurement from a “transactional” role to a “strategic” one. By automatically evaluating freight, sustainability, and cost across thousands of variables, the margin on raw materials has improved by 4.5% year-over-year.

Why It Worked: The JumpModel Assessment

Mark looked at me and smiled. “Remember when we thought AI was just for writing emails?”

The reason this company reached Level 4 while their competitors are still struggling with “manual workarounds” is simple: they didn’t start with the AI. They started with the JumpModel Assessment.

We didn’t just “turn on” IFS.ai. We identified the underutilized modules and the data readiness issues that would have throttled the AI’s potential. We moved them from a “noisy” system to a performance engine.

The Roadmap to 2027 Starts Now

The vision for 2027 isn’t about more technology; it’s about less noise and more results. It’s about a system that doesn’t just tell you what happened, but tells you what to do next.

If you’re still using 30–40% of what you’re paying for, you aren’t just missing out on features—you’re missing out on the cash flow that will fund your future growth.

Are you ready to build your roadmap to 2027? Let’s grab a coffee. We’ll show you where the hidden value lives.