The IFS Cloud Superpower: Mixed-Mode Manufacturing

Some Context

In today’s dynamic manufacturing landscape, companies are constantly seeking ways to optimize their operations and drive growth. One key aspect that often goes unnoticed is the alignment of production processes with the appropriate mode of manufacturing. JumpModel recently completed some research that indicates that as many as 60% of North American manufacturing companies operate in more than one “mode of production.” This misalignment can have dire consequences in the way of increased costs and decreased customer satisfaction. In this article, we will explore how the remarkable capabilities of the IFS Cloud can act as a superpower in enabling mixed-mode manufacturing.

Let’s begin by defining mixed-mode manufacturing. In a nut-shell Mixed-mode manufacturing refers to the coexistence of different production processes within a single manufacturing environment. You’ve heard of Make-to-order? Make-to-stock? Those are two you’ve probably heard of.

The Intrigue

Would you believe that at times, manufacturers go years, even decades, without realizing that their ERP misaligns with their true-to-life modes? For instance, say a plant that should be 40% Make-to-stock and 60% Make-to-order is actually reflecting 100% make-to-order in their ERP configuration. This might mean they are holding 30-40% too much inventory! Ouch!

This not only hampers their ability to maximize profitability but also limits their potential for growth and customer satisfaction. It goes without saying that it is crucial for manufacturers to identify and rectify these misalignments to unlock hidden value in their operations.

These misalignments can have a significant impact on the overall efficiency and profitability of a company. For instance, if a job shop process is incorrectly matched in the ERP as a make-to-stock (MTS) process, it can lead to excess inventory and wasted resources. On the other hand, if a make-to-order (MTO) process is mistakenly treated as a repetitive process, it can result in delays and ultimately, dissatisfied customers.

Taking Action

In walks IFS Cloud. Bump badda bum!

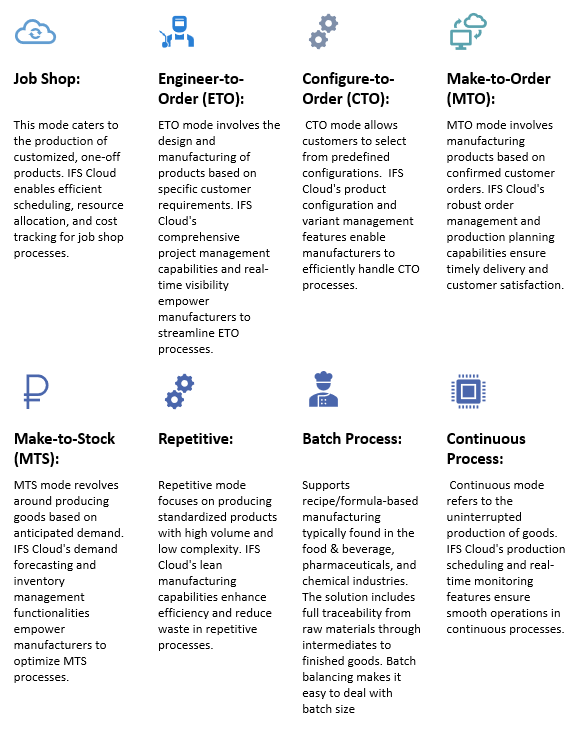

IFS Cloud, with its seamless handling of various modes of manufacturing, provides an exceptional solution to this challenge. Right out of the box, IFS can handle all of the below modes without breaking a sweat.

Some say keeping it simple is an advantage. We say pish-posh to that! You’ve got a calculator to do all of the work for you. Imagine a scenario where half of your products require CNC lathes, while the other half necessitate CNC mills. In this situation, it would not be advantageous to simplify the process by eliminating the lathes and routing all items through the mills. Such an approach would lead to disastrous consequences. You may be doing this right now with your ERP setup.

If your firm is suffering from mode misalignment, you may unknowingly be leaving valuable cash on the table. By leveraging the power of the IFS Cloud with JumpModel as your implementor, you can align your production processes with the appropriate modes and unlock hidden value in your manufacturing operations. Don’t let misaligned modes hinder your growth and profitability. Embrace the superpower of mixed-mode manufacturing with the IFS Cloud and propel your business to new heights of success.